Client story

Project: NABIT | Industry: Sustainability

Tech for Good delivers sustainability and operational impact for Conservation X Labs

US-based Conservation X Labs is an ambitious not-for-profit organisation with the boldest of missions: applying technology and innovation to prevent the sixth mass extinction. CC is proud to have propelled this cause by radically redesigning its genetic analysis and diagnostics tool. Our work has resulted in the test kit being much easier to use in the field and vastly more sustainable.

This is a heartening story where operational and commercial impact goes hand-in-hand with environmental progress. Because the NABIT kit (Nucleic Acid Barcode Identification Tool) is now more usable, adoption can grow among its customers of conservationists, consumers, customs agents, border officials and fisheries inspectors. The conservation cause will benefit accordingly.

Meanwhile, the redesign for sustainability and reduced plastic mass means reduced environmental impact across a range of impact categories. The project exemplifies CC’s application of deep tech innovation for environmental good – and reflects our belief that an effective sustainability strategy needn’t come at a cost to performance.

Tech for Good sustainability initiative

Our collaboration was sparked by an initiative from Isobel Ashbey, CC’s Head of Biodiversity and a champion of Tech for Good initiatives for our clients. During initial discussions, Conservation X Labs outlined its mission. The organisation focuses on leveraging technology, innovation and what it describes as ‘interdisciplinary genius’ to confront the planet’s most pressing problems. The driving belief? Humans might have brought about the threat of the sixth mass extinction, but it’s humans that have the power to reverse it.

The focus for the work was the hand-held NABIT genetic analysis kit, which was created to combat pressing conservation problems. Each year, millions of tons of seafood, timber and wildlife products are trafficked illegally, often disguised in processed form. Also, more diseases are crossing species boundaries – so emerging disease is threatening more ecosystems and people than ever before.

NABIT is a field-ready automated tool that puts the power of a genetics lab into anyone’s fingers. It can validate the identity of wildlife or a food product without the need for specialised training, equipment, reagents or continuous power. This is what makes it such a powerful asset in the fight to confront the underlying drivers of extinction by preventing wildlife trafficking, illegal fishing, seafood fraud, the spread of disease and much more.

Our primary task was to make the test kit much more user friendly for unskilled operators – with the aim of reducing errors, boosting the rate of adoption and so accelerating the organisation’s key conservation mission. But redesigning for usability always presents the opportunity to consider sustainability improvements in tandem – hence our additional focus.

User-centric design, engineering and fluidics

CC’s broad range of expertise was a good fit to complement Conservation X Lab’s own in-house technical and mechanical engineering skills. Rather than offering single-discipline support, we were able to centrally orchestrate extensive capabilities in product design, usability, mechanical engineering and fluidics. This was the key to the radical nature of the redesign, while having all the skills in one place also helped hasten and optimise the efficiency of the project.

NABIT test kit – positive operational and environmental impact

User-centric design lessens spills and risks of contamination and makes it more adoptable – boosting its conservation impact

CC’s all-in-one test kit design delivers a reduction of 45% CO2 -EQ versus the original kit

Features a 45% reduction in total mass and a 61% reduction in the volume of the shipping box (enabling more effective pallet packaging and reduced manufacturing and transport costs)

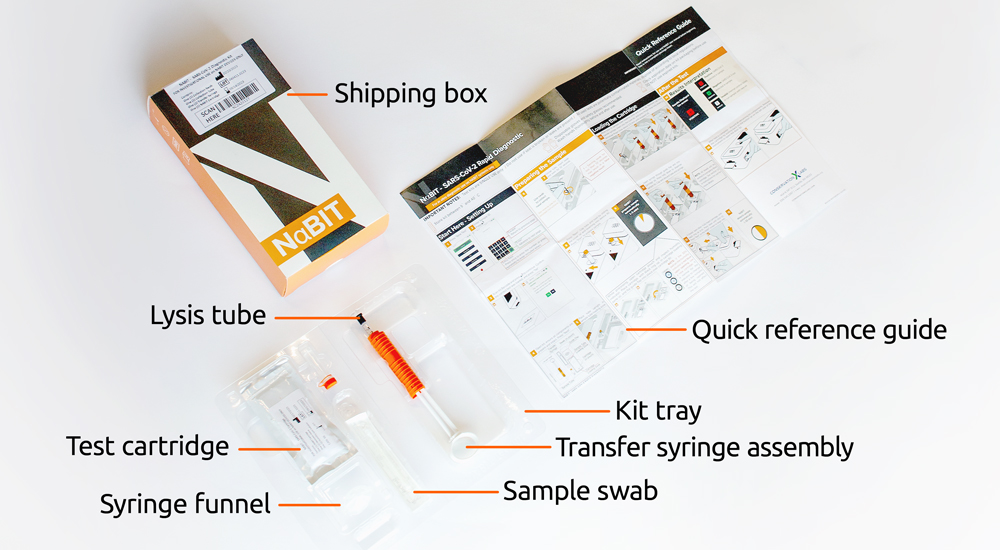

NABIT – before

This is the first-generation kit. NABIT heats the sample liquid, then a transfer syringe is used to mix buffer liquid with it. The mixture is ejected from the syringe into a test cartridge using a funnel within the packaging.

The user then inserts the test cartridge into the NABIT and runs a test to validate the identity of the sample.

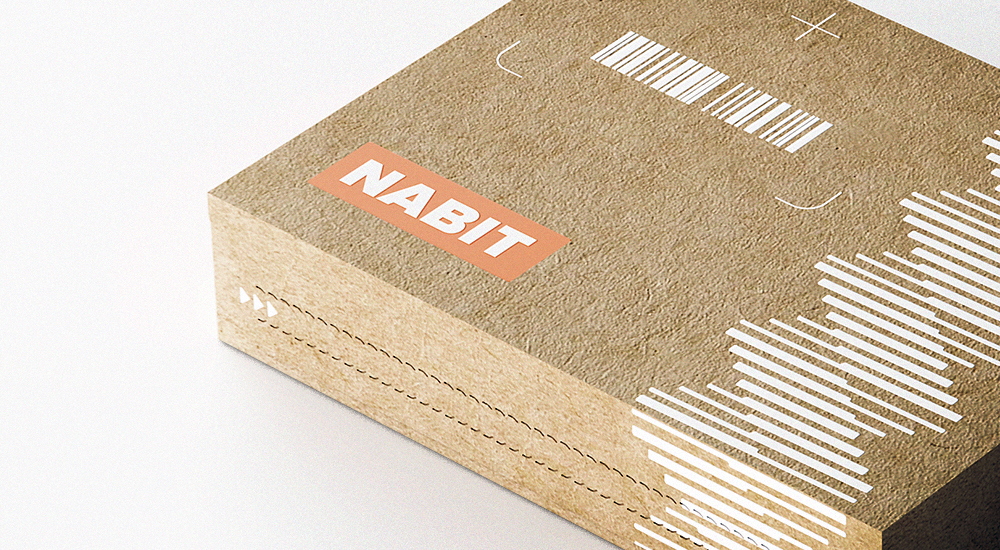

NABIT – after

This is the new kit, reimagined as an all-in-one design. CC answered the challenge of creating the most environmentally friendly and usable kit possible.

A screening lifecycle analysis (LCA) of the test kit was used to identify the most impactful areas for redesign.

Air freight transport contributed most to device impact, so reducing the volume and mass of the packed kit was critical.

Each area of the design was assessed across a range of impact categories including GWP, energy demand, water use and resource depletion. The design changes targeted improvements across a range of categories.

The new dispenser design has a 52.2% lower mass versus the transfer syringe.

The PET kit tray and PET syringe funnel were removed. Alignment features were added to the cartridge, and we designed a multifunctional paper pulp kit tray.

NABIT – problems

With the original kit, users found multiple components and interactions difficult:

Kit tray interactions – the clamshell kit tray used a lot of plastic, was space inefficient, and was difficult to interact with.

Lysis tube handling and contamination – users had to reopen the lysis tube after the sample liquid had been heated, then use a transfer syringe for mixing and drawing up the mixture before transferring to the test cartridge. This is difficult to perform and threatens contamination of the sample liquid.

Transferring liquid into the test cartridge – users struggled to align the tip of the syringe to the top of the cartridge, causing spillages.

NABIT – CC’s solutions

New packaging – a top opening tear strip box makes it easier to access components, which are laid out in the order they’re used. The new paper pulp tray removes a large amount of plastic.

All-in-one dispensing design – which solves the lysis contamination risk. The transfer syringe was removed. Instead, the lysis and diluent are contained within separate, sealed compartments that form a single, all-in-one device.

- The user introduces the sample into the lysis chamber, connects the diluent chamber to complete the system, sealing off the sample.

- Interlocking the diluent chamber seal with the device cap allows the diluent to be added to the lysis sample in a single step.

Easy cartridge dispensing – the tip of the dispenser is designed to key into the cartridge base, creating and reinforcing a seal. By pressing it down, a predefined volume of mixed solution is dispensed into the cartridge.

The dispensing tip separates from the device and maintains a seal to prevent sample contamination and leaks.

Liquid reengineering

Key to our user-centric design solution was the successful reengineering of the way liquid is moved around the system, which makes genetic analysis tests easier to perform correctly. Adam Haynes, our Senior Consultant for Strategy Design and Useability explains: “Liquid transfer approach is a term we use that encompasses the fluidics in the system and the approach used to manipulate the liquids around the test kit.

“In the original kit users handled two liquids. They swabbed a sample and dipped it into one liquid, then heated it in a device to prep it, mixed with another liquid after heating and then transferred an accurate portion of the liquid mixture to a test cartridge. The technical science of the system was fine, but the technology was undermined by the fact that it was complicated and prone to error.

“Our role was to transform the existing system to work well on the front line with real users. We were doing really clever backstage work to transform the onstage experience. So, for example, our novel mechanism for automatic mixing removed an entire sequence of user steps from the previous workflow. The all-in-one design means users no longer have to juggle three or four separate tasks.

“The engineering was laser focused on simplification. We also removed the need for users to reopen the first liquid which introduced the risk of contamination. In our design, the second liquid is waiting in an adjacent chamber ready to be mixed. And when it comes to the problem of spillage, our new approach allows users to perform a simple hand motion to transfer the liquid.”

Award winner

The NABIT design has been honoured by the globally prestigious A’Design Award & Competition.

Cambridge Consultants won the Silver A’Design Award in the Sustainable Products, Projects and Green Design category for 2023-24.

To conclude then, this story shows that radical innovation that answers the global sustainability imperative needn’t come at a cost to business and operational effectiveness. The newly designed NABIT kit is ready to further the cause of Conservation X Labs, by making it easier for people on the ground to fight back against illegal trafficking and disease proliferation. Tech for Good indeed.

Our experts

Isobel Ashbey

Senior Consultant

Adam Haynes

Senior Consultant - Strategy, Design and Usability

Charlie Dean

Head of Sustainable Medical Technology