ケーススタディー

Chiesi Farmaceutici came to us with the brief of creating a novel, next-generation dry powder inhaler (DPI) that could compete with the market leaders.

In 2013, that vision was realised as NEXThaler launched in Germany. Since then, millions of units have been sold throughout Europe, with distribution continuing to expand globally.

Competitive advantage through clear differentiation

High dosing accuracy

NEXThaler’s integral mechanical dose counter only displays fully delivered doses, ensuring patients have an accurate indication of the number of doses administered and empowering physicians to provide better patient care.

Minimising patient error, training and wasted doses

NEXThaler’s novel breath-actuated – rather than button-operated – mechanism ensures ultimate ease of use. This greatly reduces the potential for patient error, minimises training time and virtually eliminates the probability of wasted doses.

“The combination of our innovative drug formulations and Cambridge Consultants’ design expertise has resulted in a device that is very competitive towards the established market leaders.”

Flow rate independence

We designed a unique aerosol engine that ensures the maximum quantity of the drug reaches the lungs, independent of the patient’s inspiratory flow rate. This allows the device to be prescribed to the widest possible patient population.

Prolonging product life

NEXThaler accurately dispenses each dose as it’s used, eliminating the need for pre-packaged dose manufacture. The dry powder is therefore stored in a protective chamber with an integrated desiccant which absorbs residual moisture.

This allows the device to pass the stringent storage requirements required for an inhaler – resulting in a prolonged drug life of six months after opening.

“NEXThaler is more effective, efficient and preferred to use and own when compared to two leading DPI products on the market… Patients made significantly more successful uses and fewer task step failures, were quickest to set-up and also quickest to read the IFU [instructions for use].”

ケンブリッジコンサルタンツの参画

After defining detailed requirements for the device through focus groups with patients and healthcare professionals, we generated eight different concepts, turning the best two into prototypes for further focus group assessment. The final design was subjected to multiple stages of modelling, analysis and verification, including environmental and drug delivery performance testing.

We worked closely with Chiesi to successfully transfer the design to manufacture, working onsite to quickly assess any issues, recommend design changes and carry out additional testing to ensure a robust product hit the market as quickly as possible.

“Cambridge Consultants represented a ‘one-stop shop’ for all our requirements. Their long history of inhaler development meant they were able to come up with solutions to even the most complex problems and enable us to get a very successful product onto the market.”

The challenges

Breathing new life into the inhaler

Chiesi challenged us to develop a successor to its Pulvinal inhaler for both approved drug substances and drug substances in development. In light of high patient failure rates for conventional inhalers, ease of use and high performance were of paramount importance.

Inner complexity, outer simplicity

Chiesi needed their new DPI to be exceptionally easy to use and provide high therapeutic performance in a discreet, compact and attractive package. This involved many different complex features, including breath-activated drug delivery and robust dose counting mechanisms with full-dose feedback.

We assembled a cross-functional team with a wide range of expertise including industrial design, human factors engineering, fluid dynamics, design-for-manufacture and in-house analytical testing.

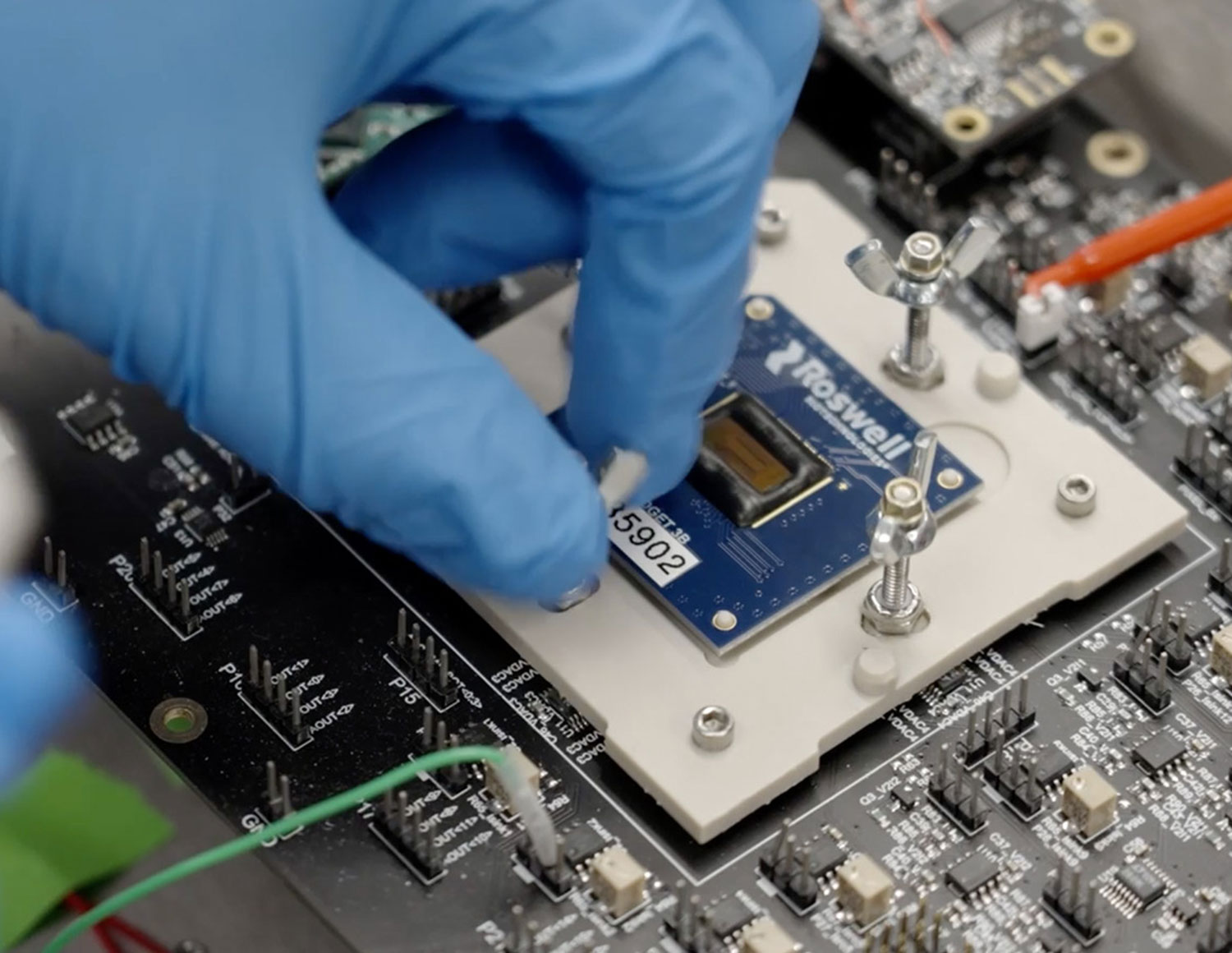

Unique inhaler test facility

We designed and built custom automated test rigs in our life sciences lab, to ensure accurate inhaler performance assessment and measure critical device functions. This enabled us to significantly reduce overall test time and cost to take the device through verification, as well as ensuring robust and repeatable results. To date more than a million doses have been tested.

開発チーム