ケーススタディー

accesso’s cutting-edge solutions are found in visitor attractions around the world.

For their latest wearable device, accesso wanted to enhance their LoQueue virtual queuing solution by creating new ways to connect with visitors.

They needed full integration with their existing systems, exceptionally reliable radio communication and an intuitive user interface – all delivered within a year and at an ambitious price point.

A uniquely carefree guest experience

Unlike anything else on the market, the accesso Prism wristband incorporates a touchscreen and three radios: Near Field Communication (NFC), Bluetooth and Long Range (LoRa).

This configuration eliminates the need for visitors to carry cash or keys or queue for attractions, whilst providing automatic photo location tagging and updates on ride times.

It also gives operators real-time guest journey data, providing valuable insight for operations, security and marketing.

Season-long, maintenance-free service

Durability and reliability were vitally important to accesso.

Prism is waterproof and can withstand up to 5 atmospheres of pressure (50m) and will operate for more than 250 consecutive days on a single battery – a world-record lifespan for a battery operated secure-element payment system with a touchscreen.

Unlike many others, the swipe-activated capacitive touchscreen is also operational when wet.

Rebrand-able

Originally a ‘nice to have’ rather than an essential requirement, Prism is modular. The customisable strap provides accesso with a product that can be re-branded for multiple visitor attraction operators.

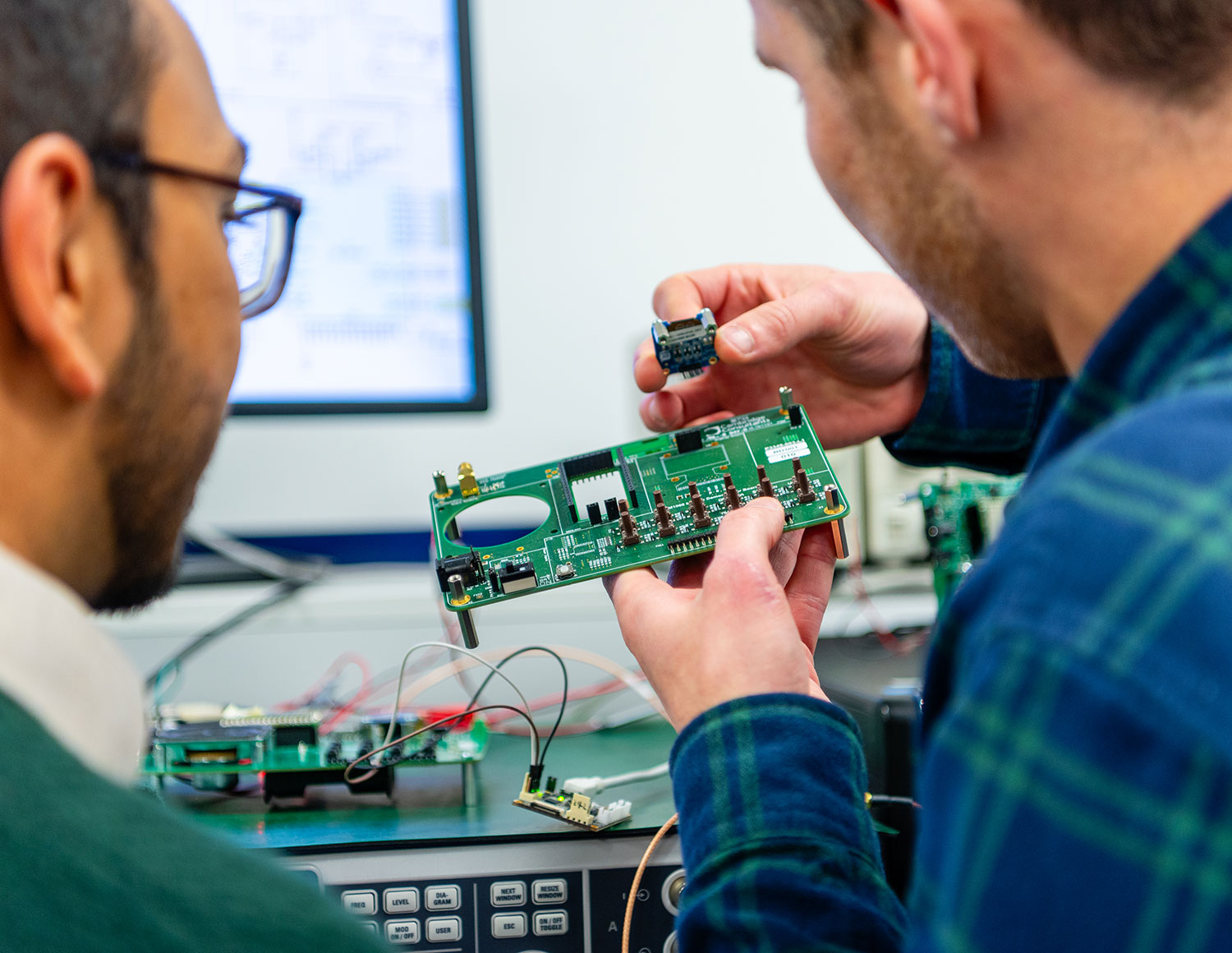

ケンブリッジコンサルタンツの参画

We developed Prism’s hardware and software designs and radio interface specification to ensure seamless integration with accesso’s existing systems.

This involved complex trade-offs between software and hardware costs and radio performance to meet accesso’s requirements for ultra-low power, secure contactless payment and rides/locker functionality.

We worked closely with accesso during transfer-to-manufacture to assess and identify the most suitable partners. We also designed the factory and production test systems and provided technical support to the contract equipment manufacturer (CEM).

We continue to support accesso through NPI and the development of new product variants.

“We came to Cambridge Consultants for their track record of delivering hi-tech, multi-disciplinary product development in very short time frames.”

課題

A visit to a theme park should be an exhilarating, carefree experience, leaving visitors with happy memories of rides and relaxation, not hours spent in queues. However, visitors to the world’s top 25 theme parks spend almost one third of their time waiting in line.

accesso’s vision was to liberate theme park visitors to spend more time enjoying themselves. But the technical challenges involved in delivering this were significant.

High density wireless network

Prism operates in one of the densest wireless IoT networks in the world, with more than 2,000 users in Europe and around 15,000 in the US, due to regulatory differences.

Our radio hardware design complies with both US and EU regulatory frameworks, with only minor component changes required for each region.

小型化

To incorporate three radio antennas into such a small package we designed a single, multi-fold printed circuit board (PCB). Relative positioning of the antennas and their on-body performance were critical considerations.

Our Satimo Stargate 64 anechoic test chamber enabled us to test early prototypes and feed the results directly into the design process, leading to a perfectly balanced device.

Further miniaturisation was achieved by reducing wall thicknesses and creating a strategic mechanical feature set to ensure simplified manufacture and assembly.

Speed of delivery

With less than 12 months from concept to delivery, we had to move straight to hard tooling for the mechanical parts.

We also provided regular drops of the software source code, including continuous integration test results, to ensure fast ramp-up ahead of launch.

Prism was delivered in full and on budget within a calendar year. This was only possible thanks to our world-class tooling, moulding and CAD modelling expertise, on-site antenna test facilities and rapid high-resolution 3D printing.

Low-power operation

Delivering reliable season-long performance required a combination of bespoke technology – including custom low-power RF protocols and high-performance multi-radio design – and novel implementations of standard technologies, such as the payment chip.

This unprecedented low-power performance was only possible thanks to the interaction between our software, electronics and hardware design teams, as well as close cooperation with external silicon suppliers.

System integration

Prism needed to integrate with accesso’s existing base station deployments as well as numerous third party systems.

Drawing on our long experience in custom RF design and embedded software, we delivered a fully integrated product using clearly defined air interfaces across the full protocol stack, from application layer to physical layer.

We handed Prism over and it simply worked – we didn’t even need to be there.

Touchscreen durability

A touchscreen is inherently more waterproof than a button interface, but preventing it from recognising false inputs when wet was extremely challenging.

The Prism touchscreen needed to operate reliably despite large temperature swings, high impact forces and all manner of fluids – from water and sweat to sunscreen and ketchup.

Following extensive development and testing, we overcame this with a custom detection grid and algorithm.

開発チーム